A big advantage is low cost and economic practicality.They provide good thermal insulation,meeting the energy-saving needs of general buildings.Their extremely light weight significantly reduces transportation and installation difficulty and cost.They possess certain compressive and impact resistance.With added flame retardants,they can achieve a Class B2 fire rating.They are easy to cut and process,adapting to complex installation conditions.

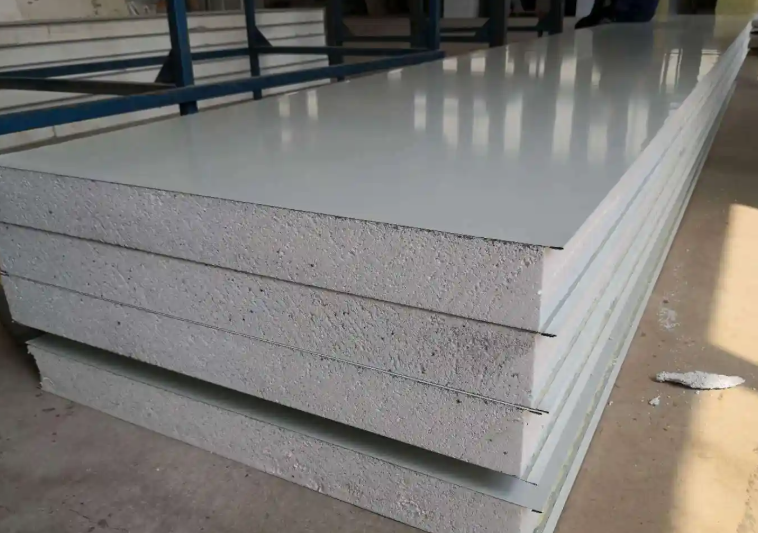

Faces often use economical galvanized color steel sheets with PE coating.EPS core density is typically 12-20kg/m³;higher density improves strength and insulation.Total panel thickness ranges from 50mm to 100mm.Standard width is 1150mm,with customizable lengths.The connection system is simple,often using lap joints or basic tongue-and-groove,allowing for fast installation.

Mainly used for walls and roofs of cost-sensitive temporary buildings and site accommodations.Also common in ordinary industrial warehouses and the envelope of steel structure plants.They are also widely used in agricultural buildings,livestock sheds,and processing workshops.Due to their lower load-bearing capacity,they are not suitable for applications with high fire or load-bearing requirements.