What is the price of cement poles?

Are you budgeting for cement electric poles for your power engineering,agricultural modernization,or infrastructure construction project?A simple search for"cement electric pole price"often yields fragmented and vastly different results because the price is far from a fixed number.This article will serve as your ultimate procurement guide.We will deeply analyze all key factors affecting the price,provide the latest market reference prices,and advise you on how to choose reliable suppliers to help you make the most informed purchasing decision.

I.Core Factors Affecting Cement Electric Pole Prices

Understanding the following factors is key to obtaining accurate quotes and avoiding cost overruns.

Specifications and Types

Voltage Level:Low-voltage poles(e.g.,0.4kV)and high-voltage poles(10kV,35kV)have different requirements for materials,craftsmanship,and insulation performance,leading to significant price differences.

Structure and Shape:Mainly include Tapered Poles(conical)and Cylindrical Poles.Tapered poles are most widely used and cost-effective;cylindrical poles are used for special load-bearing scenarios and are more expensive.

Production Process:Prestressed Poles(better crack resistance,higher strength,the mainstream product)differ in price from Non-Prestressed Poles.The former is more suitable for most applications.

Dimensions and Mechanical Parameters

Length:This is the most basic price determinant.Common specifications are 6m,7m,8m,9m,10m,12m,15m,etc.As length increases,material usage and production costs rise accordingly.

Top and Bottom Diameter:Specifications are usually expressed as"φ190×350×9m",meaning a top diameter of 190mm,bottom diameter of 350mm,and length of 9 meters.The sturdier the pole,the more material used,and the higher the price.

Load Capacity:Classified into different grades according to national standards(e.g.,Grade B,C,D).Higher load capacity requires more internal steel reinforcement and higher-grade concrete,increasing the price.

Raw Materials and Production Costs

Price fluctuations of raw materials such as cement,steel(mainly rebar),and sand and gravel directly affect the cost of the finished poles.Furthermore,the factory's production technology,energy consumption,and labor costs are also components of the price.

Purchase Quantity

The order quantity is a critical factor affecting the unit price.Large bulk purchases usually qualify for significant wholesale discounts,while small orders(e.g.,a few poles)incur higher per-unit production and logistics costs.

Transportation and Logistics

This is the most easily overlooked yet potentially huge cost variable.Freight costs depend on:

Transport Distance:The distance from the factory to the construction site is a primary factor.

Vehicle Restrictions:Extra-long poles(e.g.,over 12m)require special vehicles for transport,which costs more.

Road Conditions and Fuel Costs:The final cost requires comprehensive calculation.

Crucial Note:Factory quotes are usually FOB(Free On Board)prices,but you need to calculate the CIF(Cost,Insurance,and Freight)price to your site.The difference between the two can be substantial.

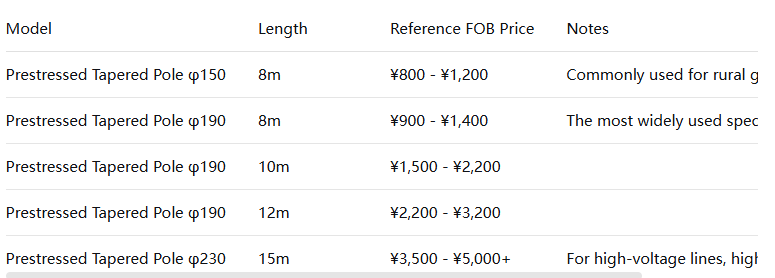

II.2025 Cement Electric Pole Market Reference Price Table

Below is a general reference range for FOB prices(RMB,VAT included)for common specifications of prestressed conical cement poles.

Important Notice:This price table provides a general market range for early 2024.Actual prices are greatly influenced by raw material market fluctuations,purchase quantity,and transport distance.It is for budget reference only.Always rely on the supplier's final formal quotation.

III.How to Choose a Reliable Cement Electric Pole Supplier

Price is important,but quality concerns project safety.Don't risk significant losses for minor savings.

Corporate Qualifications and Certifications:Check if the manufacturer has essential certifications like ISO9001 Quality Management System and Power Industry Network Access License.

Production and Quality Inspection Capability:Understand if their production process(centrifugal molding,steam curing,etc.)is standardized and if they have a well-equipped lab for cement and steel strength tests.

Project Cases and Reputation:Review the supplier's past project cases,especially collaborations with large power companies and municipal projects,and try to obtain customer references.

After-Sales Service:Check if they provide professional technical consulting,logistics coordination,and solutions for quality issues.

IV.Recommended Professional Procurement Process

Follow these steps for a smoother procurement process:

Define Requirements:Determine the required specifications,quantity,strength grade,and exact project delivery location.

Screen Suppliers:Identify 3-5 qualified manufacturers through B2B platforms,industry referrals,etc.

Request Quotations:Provide detailed requirements and ask for a clear quotation listing all terms:unit price,taxes,freight,payment methods,etc.

Comprehensive Comparison:Compare quotes,product quality,payment terms,and after-sales service from different suppliers,not just selecting the lowest price.

Factory Audit and Samples:For large orders,arrange a factory visit if possible.Request samples for inspection if necessary.

Sign Contract:Specify all details in the contract,including specifications,quantity,price,delivery time,acceptance criteria,payment methods,and after-sales terms.

Conclusion

Procuring cement electric poles is a professional task requiring comprehensive consideration of technology,cost,and service.Simply comparing price numbers is meaningless.Understanding the factors behind the price and choosing a quality-reliable,service-professional partner is the core to controlling total project costs and ensuring smooth project progress.

Post RFQ

Post RFQ

ALL CATEGORIES

ALL CATEGORIES